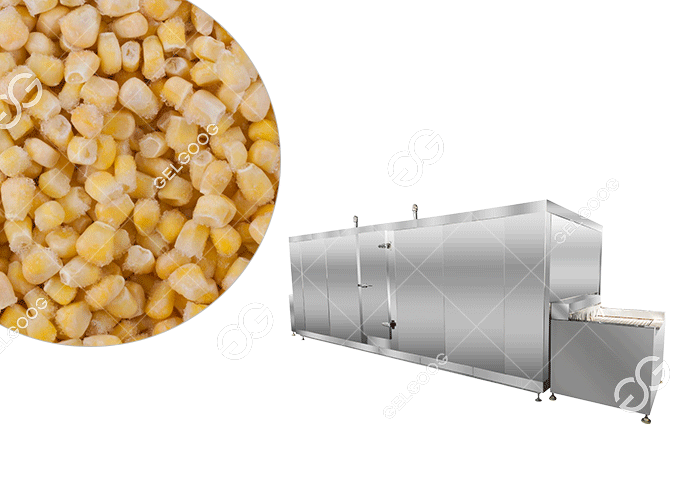

Quick-freezing is to quickly freeze the pretreated sweet corn kernels, so that the water in the cells can be frozen quickly, without damaging the corn cell tissue, and can be stored for a long time. After thawing, the juice in the tissue is rarely lost, and the original color and flavor of the corn kernels are better maintained. It is often eaten in salads and food.what is iqf corn?

How is frozen corn processed?process flow

- Raw material harvesting→acceptance→removing bract leaves and filaments→inspection→trimming→rinsing→threshing→cleaning→blanching→cooling→selection→ice water precooling→draining→quick freezing→screening→vacuum packaging→refrigeration→inspection

- Peeling and removing filaments: After the sweet corn enters the factory, it should be spread out in a cool place, and immediately peeled and processed. The time from harvesting to processing should not exceed 6 hours.

- Selection, trimming, and grading: Firstly, the ears of sweet corn that are too old, too tender, excessively moth-eaten, extremely irregular, and seriously damaged and deformed are removed. Use a knife to dig out the moth-eaten, variegated and damaged kernels from the ears of sweet corn with a small amount of moth-eaten, variegated kernels and damaged deformed kernels.

- Cleaning and threshing: Wash the graded ears of corn with flowing water, and thresh them with a special corn shredder. Adjust the knife edge on the chipper so that the knife edge just touches the cob of corn.

- Blanching: The threshed corn kernels should be blanched immediately, which can be done with boiling water or steam. Jacketed pots are generally used for boiling water blanching, and steam blanching can be carried out with steam vehicles. The heating temperature is 95°C to 100°C, and the blanching time is about 5 minutes.

- Cooling: The blanched corn kernels should be cooled immediately, otherwise the product quality will be affected.

- Sorting: Manually pick out cob cuttings, filaments, discolored grains and other impurities in time to reduce the pressure of screening before packaging and ensure product quality.

- Quick-freezing: The quick-freezing of corn kernels uses a fluidized bed quick-freezing tunnel. The corn kernels are laid flat on the conveyor belt, and multiple fans under the conveyor belt blow cold air upward at a speed of 6-8 m/s, making the frozen sweetcorn kernels in a suspended state. The evaporation temperature of the machine is -34°C to -40°C, the temperature of the cold air is -26°C to -30°C, the thickness of the corn kernels is 30-38 mm, and the center temperature of the corn kernels reaches -18°C after freezing for 3-5 minutes. Can. The quick-frozen corn kernels should not stick to each other and have no frost on the surface.

- Screening: For the quick-frozen corn kernels, impurities, defective kernels and broken kernels should be further removed. If necessary, a 0.4 cm sieve can be used for screening.

- Packaging: Quick-frozen corn kernels should be packaged at -6°C. Generally packed in polyethylene plastic bags, 250g/bag or 500g/bag as needed. Seal after packaging, and print the production date on the seal at the same time, and send it to the refrigerator for refrigeration immediately after packing.

- Refrigeration: The temperature of the refrigerator should be below -18°C and the relative humidity should be 95-98%. The temperature fluctuation range in the refrigerator should not exceed ±2°C. When stacking, there must be enough space between stacks to facilitate air circulation and uniform storage temperature.

Do you know about the processing of frozen sweetcorn kernels? Do you start a frozen corn kernel processing business? If you are interested, you can contact us. We are a frozen corn kernel processing manufacturer, and we will provide you with solutions and quotations.