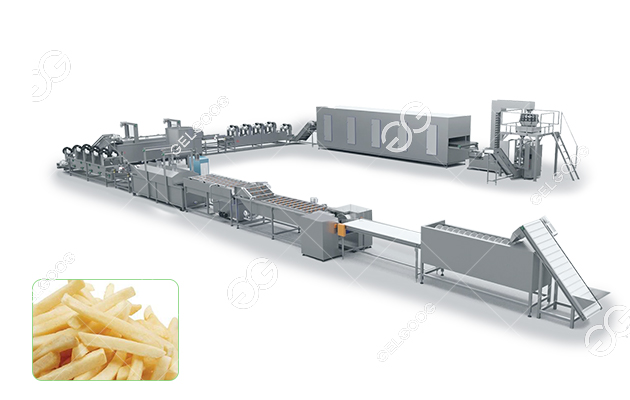

Description

The fully automatic frozen french fries production line cuts potatoes into quick-freezing, which can realize mass production. The quick-frozen French fries are convenient for secondary processing. At present, the production capacity of quick-frozen French fries that our company can provide is between 100-1000kg/h, and order is supported.

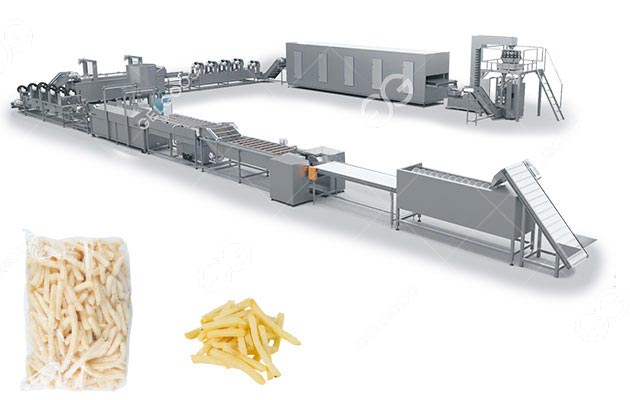

Process Of Fully Automatic Frozen French Fries Production Line

The process of the fully automatic frozen french fries production line mainly includes potatoes-washing and peeling-cutting-blanching-dehydrating-quick freezing-packaging.

- Pick potatoes: Choose high-quality, non-rot potatoes, so as to ensure that the quality of the processed quick-frozen French fries is better.

- Cleaning and peeling: Put the potatoes into the brush washing machine for cleaning, and the brush can also achieve the peeling effect during the cleaning process.

- Cutting The peeled potatoes are cut into fries by a high-speed fries cutting machine. The size of the fries can be adjusted.

- Washing: The cut French fries are put into the bubble cleaner for cleaning, and the debris on the surface is cleaned under the action of the bubble impact.

- Blanching: Blanching can inhibit the activity of mildew, play a role in color protection, and can effectively prevent the surface of fries from oxidation.

- Vibratory water remover: After blanching, there will be water on the surface of the fries, and the water on the surface needs to be drained.

- Quick freezing: Put the French fries into a fluidized quick-freezer machine for quick freezing, and the quick-freezing temperature is controlled below -36 degrees to ensure that the core temperature of the potato product drops below -18 degrees.

- Packaging: the quick-frozen finished product is packed in bags or boxes for sale.

- Refrigeration: The packaged quick-frozen French fries can be stored in a freezer or a freezer.

Frozen French Fries Production Machine

This fluidized quick-freezer makes the food blown by a cold wind from bottom to top during the process of entering the fluidized mesh belt, so as to experience three stages of cooling, surface freezing, and deep freezing to achieve the effect of rapid freezing. Has the following characteristics

- Using high-quality stainless steel materials, durable.

- High freezing efficiency, can realize continuous quick freezing of food.

- The mesh belt and quick freezing time are adjustable.

- There are many types of quick-frozen products and a wide range of applications.

- Low energy consumption, support customization.

Finally, the video below can help you better understand the operating process of the quick-frozen french fries machine. If you want to know more details about the fully automatic frozen french fries production line, you can leave me a message.